This assessment aids prioritize cleaning initiatives and target crucial spots that pose the very best possibility to item high-quality and patient basic safety.

Worst situation circumstance of all of these aspects needs to be regarded as. Moreover, ample sampling details and sampling methods must be described in the system. Also, the surfaces and the kind of residues to be detected have to be decided. Ultimately, the maximum appropriate residue limit needs to be predetermined.

In these analyses, we take a look at for compounds existing in the actual clinical solution. Applying our precisely evaluated and certified methods, we will detect leachables acknowledged for being found in consumables in nearly all sophisticated pharmaceutical answers.

This danger assessment — educated by our proprietary Extractables Simulator (ExSim) platform, which predicts the focus of extractables for one-use techniques and assemblies and scales knowledge correctly based upon process desires — is the thorough first step of the validation

Validation Master Program: Acquiring a validation learn plan that outlines the general validation strategy, like cleaning validation, is important for keeping regularity and compliance.

Besides our Extractables click here Evaluation, we also give Extractables Scientific studies to determine and prevent potential leachables for your closing drug solution. Extractables Experiments are merely what you require through the selection of appropriate packaging elements or processing products, e.

Continuous monitoring: The efficiency and regularity of the cleaning treatment should be constantly monitored. Periodic validation and regular checking are required to be sure compliance with regulatory specifications.

Ultrasonic washing: With ultrasonic washing, organizations use ultrasound & cleaning methods to clean intricate elements & components.

The validation review: The power with the cleaning protocol to effectively take out contamination from the power and products needs to be validated. The validation analyze is required to exhibit the cleaning process and protocol are productive and strong.

Cleaning validation in the pharmaceutical industry requires many jargon and abbreviations that are very important for producing staff to become aware of. Here i will discuss twelve popular phrases relevant to cleaning validation as well as their definitions:

Scientific pharmacists play a vital purpose in healthcare configurations, they are specialized in the choice of medicines and guaranteeing their Protected and effective use.

• the description of your tools for use, click here including an index of the products, make, product, serial selection or other exclusive code;

Companies must produce a validation protocol that outlines the specific assessments and acceptance criteria for each cleaning technique. The protocol must consist of specifics like sample sizing, sampling destinations, analytical methods, and acceptance limits.

It should be converted into milligram by multiplying the QC outcome with the quantity of rinse in Kg (i.e. amount of h2o for remaining rinsing in Kg).

Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Jenna Jameson Then & Now!

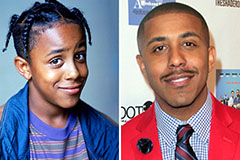

Jenna Jameson Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!